Every organization, regardless of its size or industry, incorporates some form of procurement strategy, ranging from informal, ad hoc methods to comprehensive, meticulously documented practices. While the methodologies for managing and monitoring procurement expenditures may differ, it is crucial that the fundamental definition and understanding of the procurement process remain consistent.

So, what exactly is procurement, and why is its definition significant for a company's success? This comprehensive guide will help you learn all things related to procurement.

Contents

- What is procurement?

- Why is procurement important in business?

- Types of procurement

- Steps in the procurement process

- Stages of procurement

- Procurement life cycle

- Three components of procurement

- Procurement, purchasing and supply chain: What’s the difference?

- Procurement KPIs

- How technology can help in procurement

What is procurement?

Procurement is the comprehensive process of sourcing, acquiring, and facilitating payment for goods and services. While terms such as "procurement," "purchasing," and "sourcing" are often used interchangeably, they represent distinct elements within the broader procurement function.

Purchasing primarily revolves around the activities of ordering and delivery, while sourcing is more focused on the identification and selection of suppliers for purchasing goods. In contrast, procurement encompasses the entirety of these activities and extends further to include settlement processes, analysis of procurement data, and strategic planning for future expenditures.

Why is procurement important in business?

Procurement plays a crucial role in comprehending supply chains by facilitating the identification of reliable suppliers offering competitively priced goods and services tailored to a company's requirements. This holds true whether the company is sourcing raw materials for manufacturing, engaging marketing services, or procuring office supplies.

For instance, let's consider a scenario where a retail chain is seeking a new supplier for a crucial service, such as inventory management software. Through the procurement process, the retail chain can meticulously evaluate potential software providers to determine the one that best aligns with its business needs while ensuring cost-effectiveness. This strategic approach prevents the waste of valuable resources, including time and money, that may result from dealing with inadequate software solutions.

While cost minimization is a crucial objective in improving procurement processes, it is equally imperative to prioritize suppliers known for consistently delivering high-quality goods and services. Additionally, selecting suppliers with a proven track record of reliable performance contributes to overall customer satisfaction. Effective procurement not only optimizes costs but also plays a vital role in ensuring good customer service. Without the right procurement practices, businesses risk losing customers to nearby competitors who may offer superior products or services.

Types of procurement

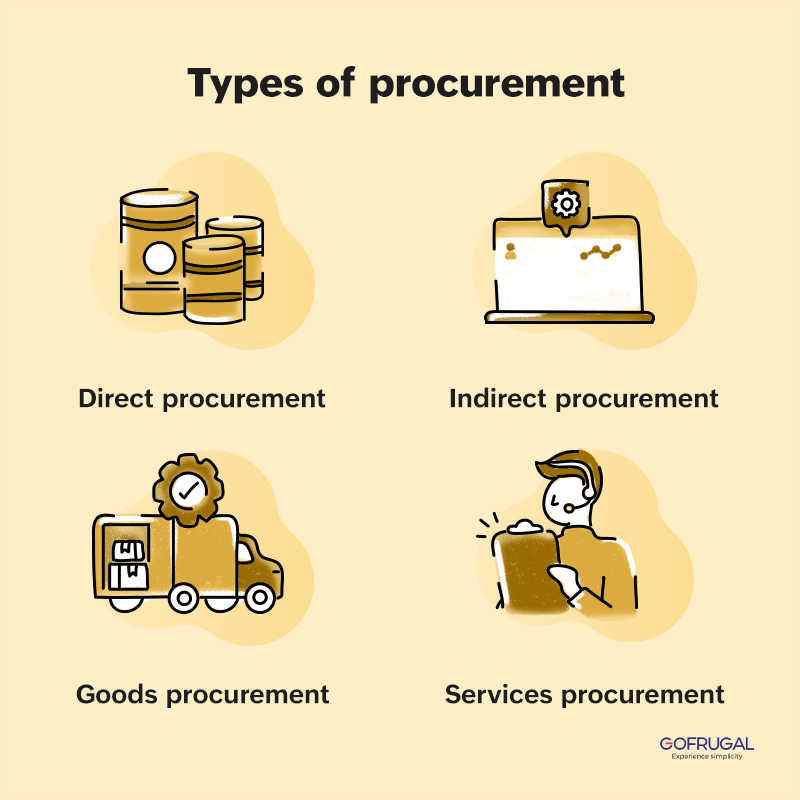

Companies adopt various procurement approaches based on their specific business requirements and immediate objectives.

Direct procurement

This involves acquiring goods and services directly linked to the production process within the organization. For example, here it involves sourcing products directly from manufacturers or wholesalers, such as clothing items from a garment factory or electronics from a technology supplier.

Indirect procurement

Indirect procurement encompasses purchases not directly associated with production activities. This category may encompass purchasing point-of-sale (POS) systems, marketing software, or retail analytics tools to enhance store operations and the customer experience.

Irrespective of whether it's direct or indirect procurement, companies typically engage in two types of purchases: goods procurement and services procurement.

Goods procurement

Good procurement is the acquisition of tangible items, whether finished products or raw materials. Goods procurement covers acquiring inventory items such as clothing, electronics, or home goods to stock retail shelves and fulfill customer demand.

Services procurement

Services procurement involves the acquisition of intangible offerings. This might involve contracting marketing agencies for promotional campaigns, hiring security services for store protection, or engaging delivery services for ecommerce order fulfillment.

Steps in the procurement process

Procurement processes vary greatly depending on each company’s structure and needs, but generally include nine core steps.

1. Identify needs

Begin by identifying the specific goods or services required, whether it's a new purchase, restocking, or renewal. Collaboration with all affected departments ensures alignment with each department's needs and specifications.

2. Submit purchase request

Formal purchase requests are made to notify the company of the requirement, including details such as quantity, price, and time frame needed. These requests are typically reviewed and approved by relevant departments or personnel.

3. Assess and select vendors

Research and assess potential vendors, focusing on factors such as cost, reputation, quality, and ethical considerations. Submit detailed requests for quotes (RFQs) to enable comparison and selection of the most suitable vendor.

4. Negotiate price and terms

Obtain multiple quotes from suppliers and negotiate terms to ensure favorable pricing and conditions. Finalize agreements in writing and ensure clear understanding and agreement of all terms.

5. Create purchase order

Generate a detailed purchase order (PO) outlining the specifics of the order and send it to the selected supplier. The PO serves as a formal agreement between the company and the supplier.

6. Receive and inspect goods

Upon delivery, carefully inspect the received goods to ensure they match the order specifications and meet quality standards. Address any discrepancies or issues promptly.

7. Conduct three-way matching

Accounts payable conducts a three-way matching process, comparing the PO, order receipt, and invoice to verify accuracy and prevent payment errors or discrepancies.

8. Managing credit days

Upon successful matching, approve the invoice and arrange for payment, while also managing credit days where applicable. Adhering to a standardized payment process ensures timely and accurate payments, fostering good supplier relationships. In many business procurements, approximately 90% are managed with credit days, which necessitates careful management to maintain positive cash flow and favorable supplier terms.

9. Record keeping and performance evaluation

Maintain comprehensive records of the entire procurement process, encompassing purchase requests, negotiations, invoices, receipts, and post-purchase activities. Understanding the performance of purchased products is vital for informed decision-making.

For instance, in the case of purchasing sarees from various suppliers, tracking consumer preferences and feedback is essential for identifying preferred suppliers and optimizing future procurement strategies. These records serve multiple purposes, including reordering, auditing, dispute resolution, and performance evaluation, contributing to effective procurement management.

Stages of procurement

The nine major steps of the procurement process can also be thought of in three distinct stages: the sourcing stage, the purchasing stage, and the receiving stage.

Sourcing stage

In this initial phase, the business identifies its requirements, generates purchase requests, and evaluates potential vendors. Establishing robust relationships with suppliers is essential even after the sourcing stage, as it fosters an environment for knowledge sharing, product and process improvements, and mutual trust.

Purchasing stage

This stage involves negotiating terms, generating purchase orders, and receiving and inspecting goods and services to ensure they meet the specified requirements.

Payment stage

Accounts payable oversees the payment process, conducting three-way matching to validate the accuracy of orders and invoices. Upon approval, payments are arranged, and meticulous records of all invoices, orders, and payments are maintained for transparency and accountability.

Procurement life cycle

Many organizations conceptualize the steps in the procurement process as a life cycle, emphasizing the interconnectedness and continuity of tasks and stages. This perspective serves as a reminder that procurement is an ongoing process with interdependent components.

It's crucial to recognize that the procurement life cycle is not always linear. In a dynamic digital supply chain environment characterized by shifting suppliers, availabilities, and costs, adjustments may be necessary to adapt to changing circumstances. This agility ensures that the procurement process remains responsive to evolving business needs and market conditions.

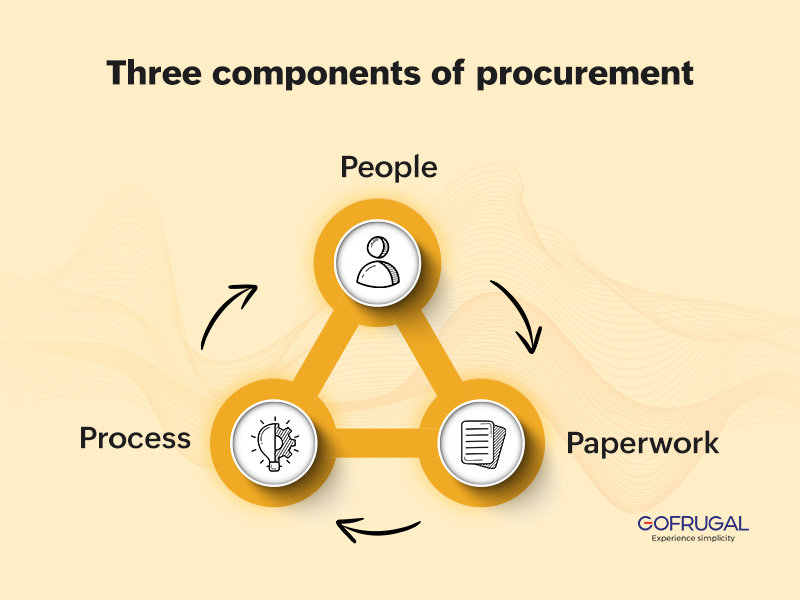

Three components of procurement

People

Individuals across various roles drive the procurement process from initiation to authorization. Collaboration among procurement specialists, accounts payable personnel, and business stakeholders ensures smooth operations. The level of involvement increases with the value of purchases.

Process

An effective procurement process is vital for cost control and timely supply delivery, fostering accuracy and timeliness through clear guidance on responsibilities and deadlines. Disorganization leads to inefficiencies, errors, and strained supplier relationships.

Paperwork

Comprehensive record-keeping is essential throughout the procurement process. Records serve as a repository of organizational knowledge, ensuring continuity and aiding in audits or disputes. Accessible documentation is crucial for compliance and tracing the procurement journey.

Procurement, purchasing and supply chain: What’s the difference?

The terms procurement, purchasing sourcing, and supply chain are often used interchangeably. However, there are important distinctions between them.

Procurement vs. purchasing

Purchasing primarily focuses on the transactional aspect of acquiring goods or services to fulfill specific orders and meet immediate company needs. On the other hand, procurement encompasses a broader spectrum of activities, including establishing and nurturing supplier relationships. Procurement takes a proactive approach by analyzing the company's requirements and strategically managing the entire procurement process, whereas purchasing tends to be more reactive, centered on obtaining what the company has already identified as necessary.

Procurement vs. sourcing

Sourcing is a crucial component of the procurement process but represents only one stage within it. Sourcing involves activities such as identifying potential suppliers, assessing their capabilities, negotiating terms, and ultimately selecting vendors that align with the company's requirements. In contrast, procurement encompasses the entire cycle of activities, from analyzing needs to obtaining and paying for goods and services.

Procurement vs. supply chain

Procurement constitutes a subset of supply chain management, covering the sourcing, acquisition, and payment for goods and services required by the organization. Supply chain management, however, encompasses a more extensive range of functions beyond procurement. It includes logistics aspects such as transportation, warehousing, and inventory management, as well as activities involved in transforming raw materials into finished products and distributing them to customers.

Procurement KPIs

By monitoring key performance indicators (KPIs) in procurement, businesses can enhance process efficiency, track progress towards strategic goals, and pinpoint areas for optimization. Here are some commonly measured procurement KPIs.

- Purchase order cycle time: This metric tracks the average duration, in hours or days, from requisition to sending purchase orders to suppliers.

Purchase order cycle time = # of hours or days it takes to process requisitions and send purchase orders to suppliers / # of purchase orders sent to suppliers

- Supplier lead time: It measures the average number of days taken by suppliers to deliver items after receiving a purchase order.

Supplier lead time = # of days it takes for item(s) to arrive after supplier receives purchase order / total # of purchase orders sent to supplier

- Number of suppliers: Monitoring the count of suppliers in the network helps balance options against administrative workload, with periodic pruning of less-utilized suppliers to boost efficiency.

- Supplier defect rate: This metric evaluates supplier quality by calculating the ratio of defective parts to the total supplied.

Supplier defect rate = # of defective parts from vendor / total # of parts from same vendor

- Supplier availability: It gauges each supplier's responsiveness to last-minute or emergency demands by comparing fulfilled orders to orders sent.

Supplier availability = # of times supplier fulfilled business orders / # of orders sent to supplier

- Fulfillment accuracy: This metric assesses the percentage of accurately filled orders compared to the total orders from the same supplier.

Fulfillment accuracy = # of accurate orders from supplier / total # of orders from same supplier

- Total ROI of the procurement process: This KPI quantifies the value delivered by the procurement strategy, calculated as the ratio of annual savings generated by procurement to the total annual procurement expenditure.

How technology can help in procurement

Gofrugal offers practical solutions tailored to address common procurement challenges, empowering businesses with a comprehensive suite of features to streamline operations and drive efficiency across the procurement lifecycle.

- Centralized procurement: Effortlessly manage the end-to-end procurement process from requisition to payment, ensuring reduced errors and heightened accuracy.

- Supplier management: Build robust supplier relationships through access to supplier reviews and transparent communication channels, fostering seamless collaboration and trust.

- Standard policies: Define and enforce standardized procurement policies to promote clarity, consistency, compliance, and risk mitigation.

- Advanced planning: Use Gofrugal's ERP system for proactive procurement planning based on insightful reports and stock audits, facilitating informed decision-making and optimal resource allocation.

- Automation: Automate procurement touchpoints to minimize manual errors and streamline processes, enhancing operational efficiency and cost-effectiveness.

- Digitized purchase system: Digitize the entire purchase process to facilitate informed purchasing decisions, ensuring timely sourcing of the right products at the optimal price points, thereby driving profitability and growth.

With Gofrugal's comprehensive procurement solution, businesses can optimize operations, strengthen supplier relationships, and achieve sustainable success in today's competitive market landscape.