Key takeaways:

- Understand what the inventory turnover ratio (ITR) is and how it affects business performance.

- Learn how to calculate your ITR and interpret its significance for your business.

- Discover what constitutes a good ITR and why it matters for profitability.

- Explore five key lessons to improve your inventory turnover and boost efficiency.

- Find out how adopting the right solutions can enhance your inventory management and service.

Before we talk about the Inventory Turnover Ratio, I would like to talk to you about the new bike I got for myself. But I still remember my first bike. It was a gift from my dad, who would not let me off the hook easily. He wanted me to learn everything about the bike, including how to ensure I get good mileage. I went like, ‘What’s a mileage?’ The mileage of a vehicle is the number of miles it can travel using one liter of fuel. Mileage is an important indicator of a vehicle’s condition. It is like a health check indicator for your vehicle. So, is the Inventory Turnover Ratio for your business. Ultimately, the optimum Inventory Turnover Ratio results in how well your business generates more sales with the right inventory.

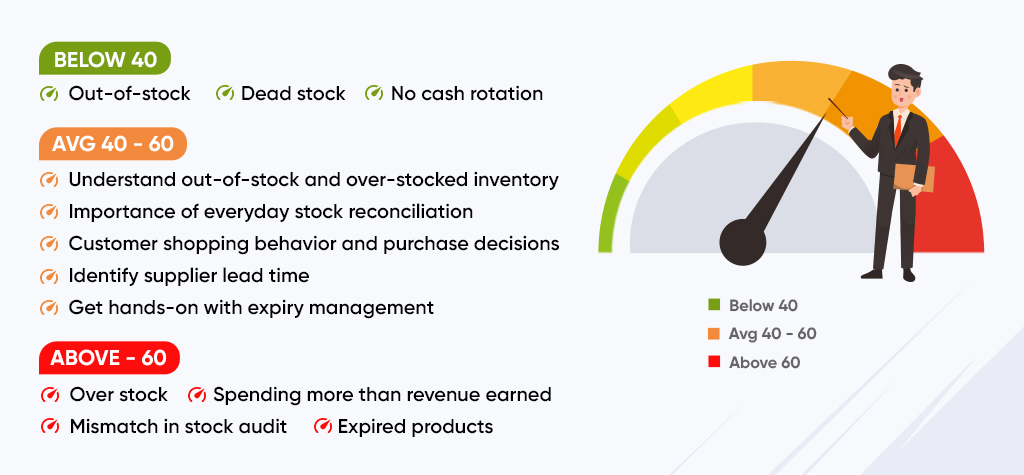

The best way to achieve good mileage is to maintain an optimum driving speed, which helps with fuel consumption and the engine’s performance. My dad advised me to maintain driving speed between 40 and 80. Without understanding speed, there is no way to achieve good mileage. Similarly, it is not easy to achieve the right Inventory Turnover Ratio without understanding the speed of stocking your inventory. Go below 40, and you lose fuel, just like you lose customers due to understocking. Speed above 80, and you end up with decreased fuel economy due to tire rolling resistance and air resistance, just like how overstocking leads to dead stock in your inventory.

Ufff! Let me take you on a ride to understand everything you need to know about Inventory Turn over Ratio! It looks like a challenging ride. But don’t we love riding once we understand all these concepts. So, hop on with me, and don’t forget to wear your helmets.

What is Inventory Turnover Ratio?

My dad always believed in starting from the basics. You really cannot get your license without taking up a test and learning the terms used on the road. So, what is the Inventory Turnover Ratio?

The Inventory Turnover Ratio measures the rate of sales and replenishment of an item over time. Inventory Turnover is calculated by dividing the cost of goods sold by the average inventory for the same time period.

In simple terms, the Inventory Turnover Ratio reflects how fast a company sells an item and is used to measure sales and inventory efficiency. Inventory Turnover is also known as inventory turns, stock turnover, or stock turn.

How Do You Calculate Inventory Turnover Ratio (ITR)?

Companies can calculate the Inventory Turnover using the standard method that includes either market sales information or the cost of goods sold (COGS) divided by the inventory. Start by calculating the average inventory in a period by dividing the sum of the beginning and ending inventory by two:

Average inventory = (beginning inventory + ending inventory) / 2

You can use ending stock instead of average inventory if the business does not have seasonal fluctuations. More data points are better, so divide the monthly inventory by 12 and use the annual average inventory. Then apply the formula for Inventory Turnover:

Inventory Turnover Ratio = Cost of Goods Sold / Avg. Inventory

What Is a Good Inventory Turnover Ratio?

If you’ve to put a number as good mileage, it might vary based on the vehicle, type of fuel used, and the number of years it has been on the road. Similarly, a good Inventory Turnover Ratio depends on the nature and size of the business. But based on the research from different businesses, a good Inventory Turnover Ratio is between 5 and 10 for most industries, which indicates that you sell and restock your inventory every 1-2 months. This ratio strikes a good balance between having enough inventory on hand and not having to reorder too frequently.

5 Lessons To Improve Inventory Turnover

If you think my dad was going to let me go with just a few notes, nahh! He had a whole lecture planned on how there are more factors that help us achieve the right mileage. Similarly, to improve your Inventory Turnover, many factors come into play. We will share 5 important tactics that can improve your Inventory Turnover.

Don’t do Heavy Braking or Acceleration on your stocks!

Aggressive driving forces your vehicle to switch gears faster than is optimal for fuel efficiency, affecting your mileage. Learning to control applying breaks and accelerating is essential, similar to understanding your under-stock and over-stock situations. The pace of restocking needs to be understood clearly. In simple words, it is not the best inventory hygiene to hold more than 50% of your inventory for more than 15 days. It is also essential to understand how to apply your breaks and when to accelerate based on the nature of your journey, the road involved, and the time required to reach the destination. When businesses miss this, they either end up with an out-of-stock or under-stocked, or over-stocked situation where their cash rotation gets locked in the inventory as dead stock.

Importance of regular checking and reconciliation

Correct tire pressure plays a vital role in improving the fuel efficiency of your vehicle, and it is important you keep a check on it every day. And so is keeping a check on your stock reconciliation. A stock reconciliation is a method of auditing the physical stocks in the inventory by counting each item and matching it with the book stocks or computed stocks. It ensures there are no discrepancies in the stocks and calculates the total investments that are held in the stocks to predict the cash flow for the next year. Generally, a stock take audit must be performed by businesses at least once a year, which is a cumbersome and inaccurate process requiring more effort and time. But the best practice is to carry out an everyday stock audit to give better inventory control and help you bypass the year-end Stock Audit headache.

Understand the gear changes in your customer’s shopping behavior

My dad’s lesson three was understanding the terrain of travel and mastering the gear changes. Without understanding gears, you cannot control speed. When improving Inventory Turnover, understanding your customers’ shopping patterns based on days, seasons, location, and even time is even more important. This will help you forecast how much your customers will want to buy. If you do not understand your customers’ shopping behavior patterns better, you will end up stocking products/brands that may not sell fast. This again will end up with dead stock in your inventory. Or you will end up with an out-of-stock situation for fast-moving items. So, understanding customer behavior is significant for making the right purchase decisions.

Plan your Purchase Route with supplier lead time

The lesser the stops, the better the average you’ll get. Also, don’t mind taking a couple of extra kilometers vs. a congested city road. You will still save on fuel. Figure out your route beforehand by using navigation apps such as Google Maps. Similarly, identifying supplier lead time is crucial when you want to have seamless purchase management. Supplier lead time is the time from when the customer places an order (when the supplier learns of the requirement) to when it is ready for delivery. It varies from supplier to supplier. For example, major market brands have fixed delivery slots while local brands deliver on a need basis. The third situation is when you offer your own products and need to assess the time taken to repack bulk items. When you understand the supplier lead time and failure average, it’s easier to plan your inventory accordingly.

Don’t idle with expiry management

Idling your car is basically getting 0 kmpl. You end up going nowhere and burning fuel pointlessly. So, whenever you have to stop your car for more than 45 seconds, you should turn the ignition off, which is taken for granted. So is expiry management. To ensure expiry management happens smoothly, it is essential to capture batch accurately and expiry details during the goods inward process. When you know expiry management, you will change the warehouse stocking and selling strategies to ensure you don’t hold on to short expiry products for more days. You will start planning the inventory with the expiry of products as a significant criterion.

Adopting the right solutions for the right service!

So, it is pretty clear that we need to follow all these lessons to achieve good mileage. But the most important lesson is to service the vehicle regularly and service it in the right place. If not, you end up spoiling your vehicle and losing your money as well. That’s exactly what Inventory management software does for Inventory Turnover. It is HUMANLY IMPOSSIBLE to service your vehicle completely. It would help if you had the support of different tools to do it. So, does your Inventory Turnover.

Choosing an autonomous solution such as EYE helps you achieve the best Inventory Turnover possible. When we say autonomous, the data from the solution takes the decisions for you. There is no need for any supplier to visit your store, no necessity for feeding data into the system, does not require any set of configurations at all. The solution takes complete control of your inventory. You can identify non-moving stocks and ensure they are cleared. Work on ordering more moving stocks and make sure they are always available. The software considers the shelf life of the products, the supplier’s lead time, and automatically raises the purchase orders. There is no need for an additional workforce, including purchase managers, and there is no absolute dependency on anyone. It is completely system-based and ensures 100% transparency. By eradicating the need for manual overseeing and approval, EYE saves time and effort and improves cash flow. Its comprehensive dashboard lets you know the excess inventory in different outlets to keep a check on your supply chain health.

Now, it is up to you to decide if you want to drive with good mileage or drive on bumpy roads; put your bike on cruise control, and enjoy the ride without anxiety or palpitation. So, always remember to wear your helmet and check your engine before getting on the road. Also, remember that finding balance for Inventory Turnover is an ongoing process, and with the right digital solution, you can achieve it easily.