Any business begins and ends with cash. Without enough cash on hand, business would be stagnant, failing to meet obligations. A healthy cash flow helps meet customer demands on time, preventing fulfillment issues.

One way to ensure you have sufficient cash on hand is to have optimized Inventory days on hand. Retail, of all businesses, know inventory is the lifeline, bloodline, and headline of any business. Having ‘inventory under control‘ by knowing the right Inventory days on hand is essential to have accurate stocks available for customers, whatever be the demand. So, how do you get it right? Well, that’s what this blog is all about!

What is Inventory days on hand?

Inventory days on hand, also known as ‘days of inventory on hand’, is the measure of the number of days a business takes to sell out the average stock available. For example, consider a store with an average inventory of Rs. 10,00,000 and takes 150 days to sell them all. 150 days is the ‘Inventory days on hand.’ The Days on-hand calculation is simple with the formulas available. Let’s calculate yours in the following steps.

Why does Inventory days on Hand (IDOH) matters?

- Decreases the risk of obsolete inventory

- Predicts and responds to customer demands

- Quickens profits by increasing the sales

- Offers a consistent customer experience

- Retains customers with zero stock outs

- Reduces the inventory carrying costs

How to calculate days of Inventory on hand using Inventory days formula?

DOH calculation is very simple when you know the DOH formula that suits your business. Pick the Inventory days on hand calculation method that is convenient to your business!

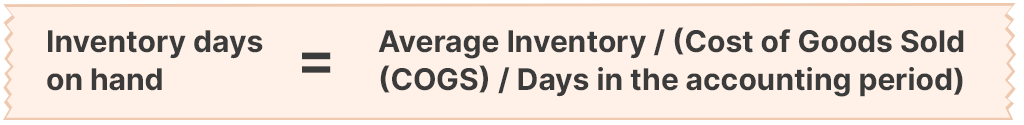

Method 1:

Inventory days on hand formula:

Here,

Average inventory = (Beginning inventory + Ending inventory) / 2

For example,

Consider Raja, who owns a retail store, wants to calculate IDOH with an average inventory of 50,000 Rs the Cost of Goods Sold for the accounting period of one year is 2,50,000 Rs.

Now the IDOH will be = 50,000 / (2,50,000/365) = 73 Days

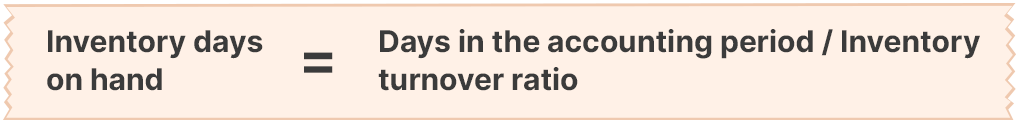

Method 2:

Inventory days on hand formula:

Note that ‘Inventory turnover ratio’ is the inverse of Inventory days on hand. Simply put, it’s the number of times you sell your inventory for a given accounting period. For example, say you have sold through your inventory 5 times in a year.

Now the IDOH will be = 365/5 = 73 Days

To know more about the Inventory turnover ratio, click here.

The above examples clearly say that it takes a period of 73 days to sell or clear the stock available. Now that you are aware of how to calculate Inventory days on hand, are you not curious to know the right IDOH for your business?

What is a good Inventory days on hand value?

There is no specific answer to say what’s the right Inventory days on hand to be maintained. Each business is unique, and the nature of business varies for a Kirana, supermarket, and hypermarket. However, any business, large or small, can calculate its own and right Inventory days on hand based on these factors:

- Suppliers’ Excellence

- Surity with Physical Inventory

- Employee’s role in decision-making

- Nature of Consumers and their shopping patterns

- Cash flow

If you are aware of the factors listed above for your business, then it is a cakewalk to manage inventory efficiently by knowing the right Inventory days on hand.

SUPPLIERS

Everything that starts in an inventory starts with a supplier. Suppliers play a crucial role in order fulfillment, and it is essential to maintain a solid relationship with your supplier. Besides checking for the quality of stocks that suppliers bring, knowing your suppliers well and understanding their potential will help you plan and procure right. To evaluate your existing suppliers’ excellence, ensure you have answers to these simple questions.

- What do your suppliers’ order processing, and fulfillment, seem like?

- What is the average lead time taken by the suppliers to process the orders placed?

- How much percentage of your suppliers deliver on time?

- If not, how many days ahead do you have to place orders so that you can fulfill customers on time?

- If you need bulk stocks, will your suppliers be capable of delivering in high volume?

Say if you have 100 suppliers and 80% deliver stocks on time, then you can evaluate if the calculated IDOH is ideal or not based on the time taken to deliver by the suppliers to your store. This helps track the lead times, measure supplier excellence, and improve forecasting of demand and supply. In addition, having a purchase management app to track the supplier’s excellence, generate timely reorders, and can help make instant inwards from anywhere allows serving consumers better without any delays.

INVENTORY

Knowing the metrics that help evaluate the suppliers’ excellence, the next in line to be understood is ‘Inventory.’ When 5 products are counted in any retail outlet, there are high chances that 2 would include a stock discrepancy. So, a stock audit becomes a mandatory activity that must be practiced to know the exact inventory before calculating the Inventory days on hand. Stores can optimize the inventory levels consistently across locations in a much simpler and more economical way without disturbing the daily operations in the store and across the supply chain easily with an inventory management app. Only when you know the existing inventory on hand can you predict, forecast demands, and make consumer-centric decisions by stocking the products right. It’s nothing when you have a stock-taking app that automatically assigns tasks daily based on the stock audit suggestions.

EMPLOYEES

It is a proven fact that if businesses aren’t implementing automation, they are falling behind others. Yes! Agile adoption of technology has refined the level of employee excellence and helps in making up smarter data-driven decisions that aid businesses to enjoy excessive operational excellence. For a retail outlet with an average of 5000 SKUs, the probability of predicting demands and making the right decision without technology is definitely tough for employees who are on a routine. One of the most distinct solutions for predicting and procuring with a consumer-centric approach can be achieved only when you allow ‘decisions to be driven by technology. Ideally, with technology, you can track, forecast, plan and automate the activities like daily reordering, transfer in-out, and control out of stock with ease backed by analysis.

CONSUMERS

To succeed in today’s competitive market, it is crucial to understand the consumer base and treat them exceptionally well for long-lasting customer relationships and retention. Knowing what the consumer wants is a tiring process if done manually. However, with the right tools in place, you can predict your consumers’ demands by analyzing the shopping trends, lifestyles, and seasonal demands so that you can purchase stocks relevant to the consumer’s needs. For example, when it’s rainy, people are highly attracted to products that are hot and spicy, like bajji flour, more than usual. Undoubtedly, raincoats and umbrellas will be the hottest products to sell through the rainy season. Here, ensuring optimum stocks are available based on the seasonal demands helps offer a better service and avoids unnecessary anxiety. When you overstock seasonal products throughout the year, the IDOH will definitely be high, which is not a good indicator of business health.

CASH

The most common problem that Indian retailers overlook is ‘Cash.’ Inventory days on hand are directly associated with Cash, as IDOH is nothing but the time during which cash remains tied up in your stock. Here it is time to pause and ask some quick questions!

How much aware am I in terms of the Cash available? Am I investing the right amount for the right quantity of stocks to be purchased at the right time?

If you are not confidently saying YES, then you fall under one of these 2 categories.

Either you spend more cash on procuring products with less demand, which leads to a higher IDOH.

Or you spend very less cash on procuring products when there is a need, and you’re about to face a serious risk of running out of stock, which leads to a lower IDOH. Both categories clearly show that you do not handle your inventory effectively and efficiently.

When your cash becomes invisible, it usually ends up in two places,

- You must have invested in products with less demand that stays stagnant as dead-stocks

- You must have invested suddenly by procuring items from suppliers who sell at a higher margin due to an unprecedented stockout

However, not to worry, you can maximize sales with the minimum inventory available by knowing the exact reorder points, procuring the right quantity, and at the right time with automation!

How can technology help me have the right IDOH for guaranteed growth in business?

Apparently, when your cash flow, inventory management, consumer behavior, and supplier-employee excellence is out of your hand, you feel tough to survive. It is humanly impossible to have control over all these factors. But, with solutions like ‘The EYE,’ it’s as easy as ABC to have control over all these and thrive expanding vertically or horizontally. Horizontal, Vertical, confusing? Simple!

You can run 5 stores at the cost of 4 when you know, clear out the cash invested in dead stocks, and start maintaining an optimized inventory!

When doing this, you can open new stores horizontally or open up new departments and grow vertically. It feels so good to hear, doesn’t it? Yes, ‘The EYE,’ an AI-based autonomous solution, drives decisions with data, 100% without any manual efforts. Single store or a multi-outlet chain, it’s all the same for The EYE. You can have control not only outlet-wise but SKU-wise.

There’s more to the The EYE solution. To know more about what our customers feel, click here.

When you know the right days on-hand inventory, and adopt data-driven decisions with technology, you are guaranteed to enjoy sustainable growth for sure!