Key features of Inventory control system

- Plan Smart purchases

- Categorize stocks

- Stock audits

- Inventory analysis

- Dead stock clearance

- Sales and Purchase returns

- Control over expiry, damage and wastage

- Refilling

- Execute Smart purchases

Plan Smart purchases

Analyze the trends with real-time data by doing perpetual inventory audits, and gain insights into every product value. Know the sales trends well, understand the demands and determine reorder points with good knowledge and visibility.

Categorize stocks

Categorize the stocks well as it helps in having a proper product distribution, easy and comfortable stock counting to data-identify the stock discrepancies and movement.

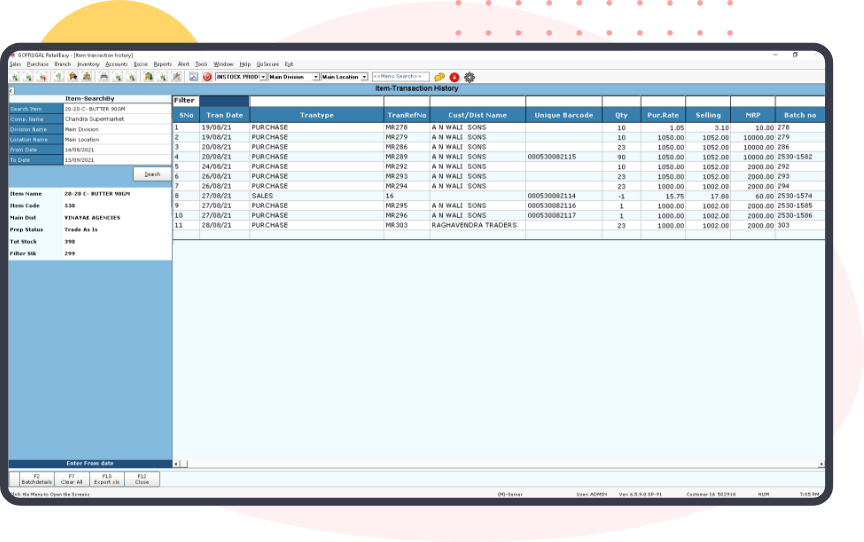

Stock audits

Evaluate the stocks properly with regular stock counting, as it helps in eliminating the back order scenarios where one has to order the items due to lack of supply which might disturb the customer satisfaction due to the unavailability of items on hand at the time of sales.

Inventory analysis

Analyze your inventory regularly to understand and bridge the gaps so that the supply can meet the demands. Stock analysis helps you know what and when the replenishment of stocks can be done to avoid interruptions. Inventory analysis can be done better by understanding the FSN (Fast, Slow, Non-Moving) analysis, where you can identify the fast-moving, slow-moving, and non-moving stocks. This analysis helps to get rid of the non-moving inventory and avoid the undesirable inventory carrying costs.

Dead stock clearance

Before restocking you have to analyze and clear the dead stocks so that you do not end up losing the precious space to store these products. When you analyze and clear these unwanted dead stocks you can save more on storage, cost spent on equipment etc. Proper analysis prevents you from being struck up with the dead stocks again and helps you know the top selling products and order based on the customer needs and demands.

Sales and Purchase returns

The purchase returns and allowances, purchase discounts, sales, and sales returns have to be made clear so that the inventory account balance remains accurately. Making the sales and purchase returns at the right time prevents inventory losses including theft, spoilage, or other losses.

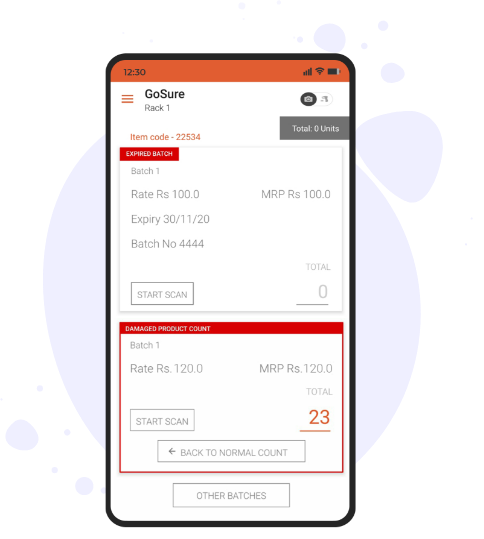

Control over expiry, damage and wastage

Severe inventory loss might occur due if the expiry, damage and wastage stocks aren't taken care of. Having good visibility over the stocks with frequent stock counting helps in analyzing and preventing the loss. Improper packaging, poor handling during transportation etc might result in the spoilage of stocks. However, proper care, and timely monitoring will help in getting control over the stocks.

Refilling

Stock refilling has to be done dynamically by analyzing the stock levels in the racks and shelves. By understanding the inventory, every item must have a minimum and maximum quantity set in advance, so that it is possible to refill the stocks before the item runs out of stock. On time refilling will help you never miss out a sale and boost the customer satisfaction levels.

Execute Smart purchases

It is highly essential to have stocks in hand stored in your warehouse so that whenever an item reaches the minimum level, they can be refilled immediately in the store. Automatic reordering helps you maintain an optimized inventory so that the purchases can be made at the right quantity and at the right time.