Key features

Key takeaways

- Understand the common reasons for stockouts and overstocking.

- Learn practical strategies to avoid stockouts and overstocking.

- Read the key benefits of smart inventory planning and how Gofrugal helps to achieve it.

Key reasons for stockouts and overstocking

- Inaccurate forecasting: Making a random guess or poor demand forecasting techniques result in inaccurate purchases, repacking, and stock transfers.

- Supplier-driven purchases: Procuring items based on supplier inputs results in ordering irrelevant items at inaccurate quantities, causing loss in margins and revenue.

- Supply chain disruptions: Unpredictable external factors such as natural disasters, labor strikes, raw material shortage, and policy changes result in stockouts.

- Lack of real-time inventory visibility: Using manual and inefficient inventory tracking methods leads to a lack of real-time inventory sync and poor inventory control.

- Poor supplier management: Over dependence on a single supplier can cause stock shortages due to late deliveries and stock dumping due to inconsistent lead times.

- Inefficient operations: Delays in reordering, GRN entry, repacking, and stock transfers causes stockouts and sometimes overstocking due to inconsistent lead times.

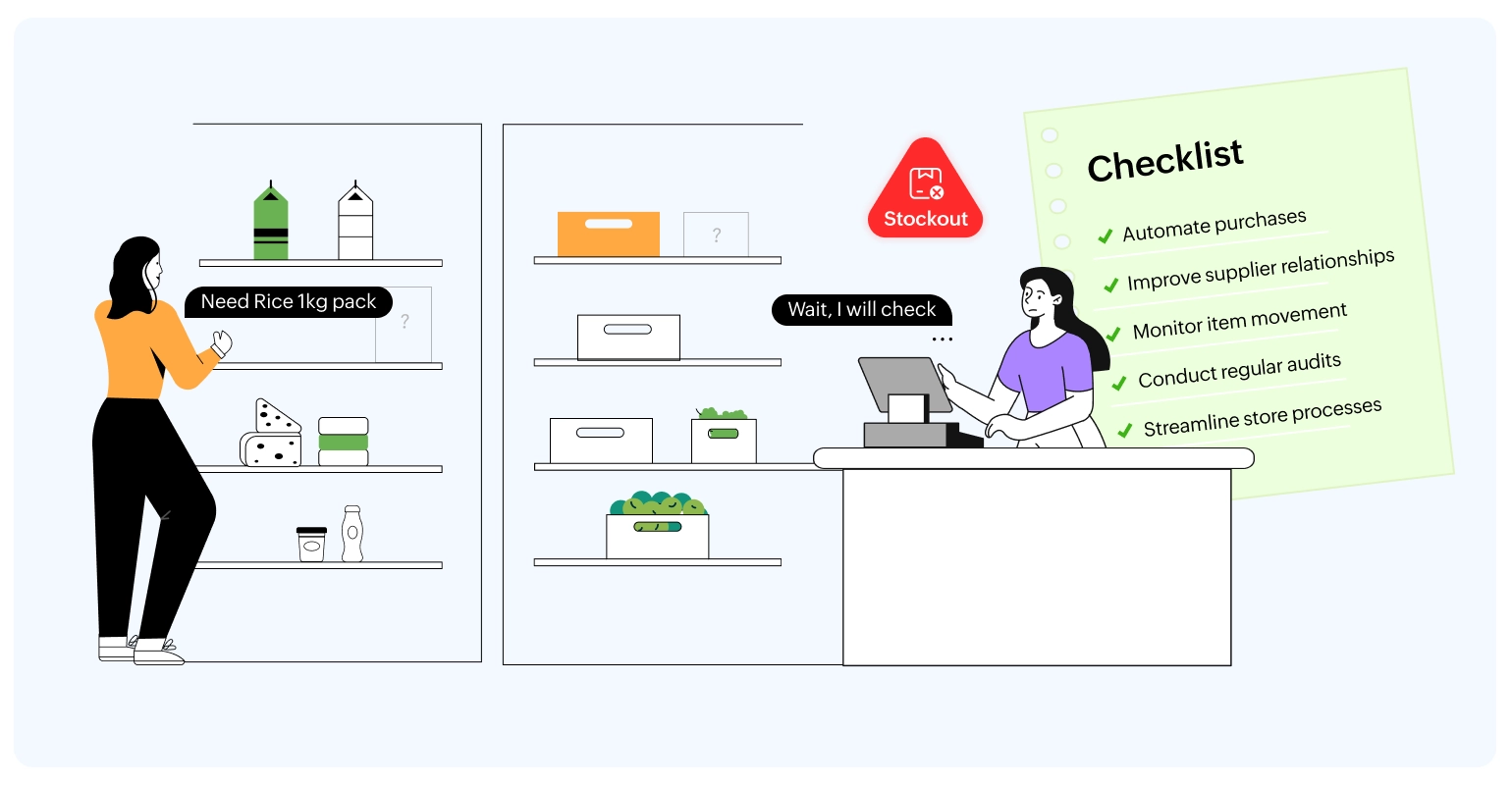

How retailers can avoid stockouts

Implement purchase automation

- Set minimum stock and reordering points to raise purchase orders before stock reaches critical level.

- Adopt AI-based demand forecasting tools to analyze sales patterns, seasonal spikes, and festive demand.

- Automate purchase orders to suppliers based on supplier cycles, sales flow, and current stock.

Strengthen supplier relationships

- Track supplier performance, fill rate, and lead time, and share transparent feedback to them for continuous improvement.

- Maintain alternate suppliers for each category of items to order in case of emergency and to ensure competitive pricing.

- Make timely supplier payments and maintain healthy relationship to ensure they take extra care to service you on time.

Monitor item movement

- Analyze fast-moving items regularly and increase the purchase frequency to meet the demand.

- Track stock levels across locations and warehouses and make orders or stock transfers to maintain sufficient stock.

- Maintain real-time inventory sync across all channels to ensure zero stockouts both online and offline.

Conduct regular audits

- Perform stock audits of all items regularly and update the system stock to ensure real-time stock visibility.

- Keep your stock across all locations updated with healthy goods counts to avoid last-minute stockout surprises.

- Conduct audits before festival seasons and important events to plan purchases based on seasonality.

Streamline store processes

- Allow billing only after making goods inward (GRN) and disable billing at counters with negative system stock for better inventory control.

- Analyze item movement, repack relevant child items at warehouses based on demand, and transfer stock to stores before inventory reaches minimum stock levels.

- Configure SMS/WhatsApp alerts for critical stock levels and refill racks immediately.

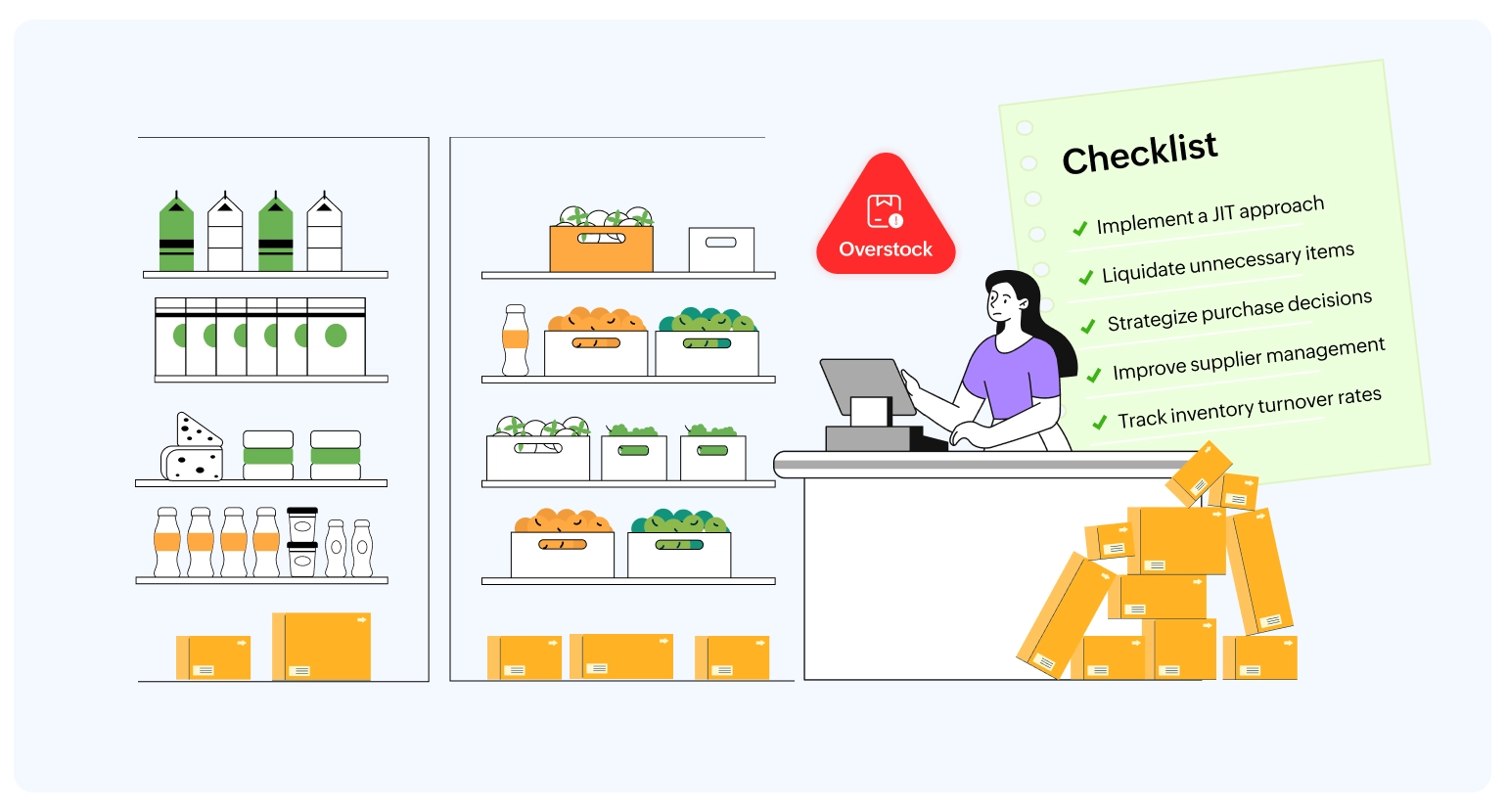

How retailers can avoid overstocking

Implement a just-in-time approach

- Analyze and procure items in different intervals based on changing customer needs instead of stocking items in bulk.

- Raise small valued purchase orders frequently only when inventory reaches minimum stock to maintain optimum stock levels.

- Store sufficient stock centrally in warehouses and transfer them to stores when needed to avoid excess purchase and optimize storage.

Liquidate unnecessary items

- Audit items, check the item condition, and return damaged items identified to ensure healthy goods inventory data is up to date.

- Identify nearing expiry and old batch items during audits and push to sell them quicker to free up space for fast moving items.

- Identify slow moving items and liquidate them through combo offers, special discounts, and strategic product bundling.

Strategize purchase decisions

- Perform ABC analysis of items and set different order cycles based on item movement even if they're serviced by the same supplier.

- Avoid procuring in bulk for offers and discounts. Compare savings from offers against inventory carrying costs and make decisions accordingly.

- Forecast demand based on past sales and automate purchase decisions without suppler influence to reduce stock dumping.

Improve supplier management

- Negotiate with suppliers for shorter lead times to reduce safety stock storage and high inventory carrying stock.

- Choose suppliers who provide flexible order quantities, timely deliveries, and better fill rates.

- Improve supplier communication and maintain friendly supplier relationships so they don't push items to meet sales targets.

Track inventory turnover rates

- Monitor how quickly each item is sold and refilled to measure the inventory turnover rate (ITR) and plan future purchases.

- Set ITR goals for each item category and location and take quick actions for items with lower ITR values.

- Configure maximum stock levels for each item based on ITR, storage capacity, and forecasted demand to avoid overstocking.

Benefits of smarter inventory planning

- Optimized stock levels: Smarter planning enables you to stock as per customer demand and preferences. Racks are always full with what the customer needs. Never miss a sale due to stockouts or pile up inventory with overstocking.

- Improved cash flow: Stocking only what is needed reduces storage costs, ensures sufficient working capital to spend on other investments, and improves the overall cash flow in your business.

- Streamlined operations: Accurate inventory planning aids in accurate purchase decisions, hassle-free repacking at warehouses, on-time stock replenishment at racks, and seamless sales at counters.

- Enhanced customer experiences: Real-time inventory sync across multiple channels enables customers to place orders online, as well as shop in-store for all their required items in one place, providing a holistic shopping experience.

- Increased productivity: Efficient inventory planning reduces manual efforts in reordering, materials inwards, repacking, and stock auditing. It reduces human errors and misappropriation and ensures transparency across the supply chain.

How Gofrugal helps manage inventory efficiently

- Batch-wise inventory control

Manage multiple batches of inventory efficiently with unique barcode and EAN code support. Implement a FIFO (first-in, first-out) approach and reduce expiry with batch-wise stock tracking. Simplify billing and handle returns easily with barcode-enabled stock. Configure minimum and maximum stock and set reorder points to optimize inventory levels. - Accurate purchase decisions

Forecast demand based on past purchases and raise reorders based on flexible conditions. Raise reorders to the correct suppliers at high profits at the right time with autonomous reordering with a few clicks. Configure supplier margin limits and ensure your profit remains intact. - Efficient repacking and stock transfers

Manage stock in multiple locations with centralized inventory control. Store items in bulk at warehouses at a lower cost and repack them into smaller quantities based on customer demand for higher profit margins. Transfer stock from warehouses to outlets and between outlets based on your needs with complete tracking and visibility. - Digitized inventory management

Audit stock regularly, even during business hours, with the StockTake app. Raise orders, inward items, and handle returns with the GRN app. Ensure accurate stock picking and on-time stock refilling at the racks with dedicated mobile apps. - Make informed decisions

Track item movement and performance with various analytical reports such as fast/slow moving, low/high margins, top selling items, and more. Monitor the sales at each counter, location, and outlet with dedicated reports to plan your reordering and repacking. Configure offers on items and combos based on reports and move the slow moving inventory.

Frequently asked questions

What is the best way to predict inventory demand?

The best way to predict inventory demand is to analyze reports and past transactions to learn sales movement, seasonal and festive sales trends, and offer performance. Using AI-based demand forecasting can increase prediction accuracy further and ensure improved inventory control.

What technology is essential for modern inventory management?

Modern retail inventory management requires a cloud-based POS system, barcode, weighing scale and RFID integration, accurate demand forecasting solutions, omnichannel integrations, mobile inventory apps, and real-time analytical dashboards for accurate and efficient inventory planning.

How can I reduce overstocking without risking stockouts?

Implement efficient demand forecasting tools and AI-based reordering to increase purchase accuracy without overstocking. Monitor item movement with inventory reports for fast/slow moving items, low/high margin items, location-wise and supplier-wise top selling items, current stock details, and more to optimize purchase decisions.

Negotiate for flexible order quantities, short lead times, and improved fill rates with suppliers. Identify slow moving and nearly expired items and liquidate them through offers, discounts, and strategic product bundling. Order small quantities in short intervals based on customer demand and not due to supplier influence or bulk offers.

How often should I conduct an inventory audit?

Inventory audits should be carried out at regular frequencies based on item movement, item category movement, purchase cycles, and seasonality. Weekly or monthly stock audits are recommended for all item categories. For fast moving items, weekly audits are best for precise demand forecasting.

You need to do stock audits after all major events such as festival season, clearance sales, store relocation, store revamp, and similar events. It is mandatory to do a stock audit at the end of each year for all items to ensure accurate inventory levels and revenue data for tax and statutory compliance.